Product Description

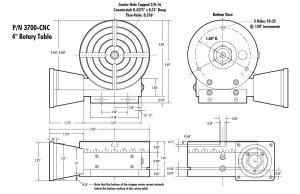

Sherline has taken its P/N 3700 manual 4″ rotary table and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame-size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

This table is also available as P/N 8700, which includes a stepper motor and a self-contained CNC controller for use as a stand-alone CNC indexer.

NOTE: We are stating the following weight limits for our rotary tables for continual use.

- Horizontal orientation—50 lbs.

- Vertical orientation—30 lbs.

- Vertical rotational torque—6 foot/lbs. (meaning it can lift a 6 lb. weight when suspended 12″ away from the center of the rotary table)

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

Using the rotary table with the limit switches on the TAT

NOTE: For instructions on using the rotary table with the limit switches on the TAT, click on the Instructions tab above and download the PDF MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.

Use in laser marking systems

Sherline’s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. See this YouTube link for a video of a Sherline CNC-ready rotary table in use in a laser marking application on a round part, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. The video is from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table. A Sherline chuck holds the part. A second YouTube video from Jimani shows a typical round part marking operation from start to finish.

NOTE: Because components of the table are ground as a set during production, the P/N 3700 rotary table cannot be upgraded to the P/N 3700-CNC version later on. A new rotary table with stepper motor worm housing must be purchased.