Sherline Gear Tooth and Thread Calculators

Joe Martin developed some calculators to help you with gear and thread calculations. They are in the form of Microsoft® Excel spreadsheets. Click on any of the links to the left or below to open these programs. (These are zipped files that need to be decompressed, and you will need Microsoft ® Excel required to open and use.)

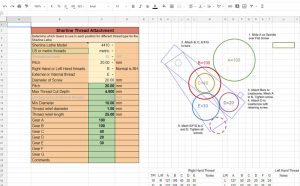

This Sherline Thread Attachment Calculator comes to us via Joo Beng Koh of Singapore. He originally posted it to the Sherline Lathe & Mill Facebook Group, and he has graciously allowed us to post his calculator link to our website. The calculator automates the gear selection based on the desired thread count.

Here is his explanation and a link to the spreadsheet calculator:

“I do use the Sherline Thread Attachment and found that it was quite tedious to set up the gears each time I wanted to cut threads. I didn’t use it that often, and the threads I cut often changed from project to project. So I created a spreadsheet on Google Sheets to “automate” the selection of the correct gears for the threads I wanted to cut. So I thought I’d share the spreadsheet in case others can also benefit from it. I hope it’s self-explanatory, but feedback to improve the sheet is certainly welcome. After selecting the parameters in light yellow, the “answers” will be shown in the green boxes. There is also an image on the right that shows which gears go where. There’s also a step-by-step description on the image to install the gears in the correct sequence. It made my life a lot easier, so hopefully, it’ll help some of you too!”

This Excel calculator will calculate the various dimensions needed to produce a helical gear. If the helical angle is set to “0,” it will give you standard spur gear dimensions. I put it together primarily to calculate the amount of A-axis rotation needed to cut a helical gear using CNC. If you enable the Macro, the program will generate the g-code that was written for a Sherline CNC mill. It may or may not work with other CNC machines. The Macro was written in 2005 using Excel 2002. On some newer computers, it sometimes puts two lines on one line or leaves the “n” off and possibly the first number at the beginning of a line, but you can correct those errors by editing them yourself in Wordpad.

Instructions for use:

- When opening the program, select “Enable Macros” if asked.

- Enter the appropriate numbers for your desired gear in the pink cells of the chart.

- Hit the [Enter] key after entering your new numbers.

- Click on the “Create G-Code” box in the grey instructions cell.

- Click “OK” in the box that says “End.”

- If the g-code window in Wordpad loads behind the Excel window, you may have to minimize the Excel window to view it.

- Review the G-code to make sure all the lines begin with the letter “n” and the proper number. (Edit in Wordpad if necessary.)

This calculator is similar to the one above, except it does not contain the macro needed to calculate helical gears.

Enter a number in the appropriate box and hit [Enter]. Convert weights between kilograms, grams, milligrams, micrograms, pounds, and ounces.

One of our Sherline customers, David Bishop, introduced us to some software for making gears. Because gear cutters for clock gears are expensive and hard to find, we are sharing this information with any of our customers who are interested. This software allows you to design your gear by entering all of your gear dimensions and information. Then it will generate a G-code program so you can cut your gears on a CNC mill. David uses one of our Sherline CNC mills to cut his gears. He uses superglue to mount his brass stock onto a piece of aluminum. Then he cuts his gears with a .030″ (.7 mm or .8 mm) diameter carbide end mill at a very slow feed rate of about (0.2 mm/min). He then heats the gear to break the bond of the superglue to free the gear from the aluminum block. The gears that David has made have a finished quality right off of our machine.

The Gear Wheel Designer program was created by Graham Baxter and can be purchased from Delph Electronics, via Steve Lunn, at this site (DelphUSA Gear Wheel Designer).

More Calculators

- Online Conversions! This link from Machine Tools Online offers some handy conversion calculators for dimensions, time, money, and more or for dimensional conversions between systems.

- More Free Caclulators, formulas, conversions, cost of living…you name it. See Cleave Books’ Specialist Calculators page at www.cleavebooks.co.uk.

- Here’s an interesting site with lots of handy software for the shop that has one major attraction…IT’S ALL FREE! Marvin Klotz has a website called Software for People Who Build Things that includes a wealth of programs for your use. It’s worth looking over the list to see if there is anything that could help you solve a problem. I’ll bet you find something you’ll download. It’s cool stuff, and the price is right.

- The Machinist’s Calculator is a valuable utility program for Machine Shop Owners, Machinists, CNC Programmers, Metalworkers, Students, Engineers, or anyone else who needs to solve Trigonometry calculations. Also a great utility tool for cad or cad-cam users. It’s available for purchase but also is offered as a 30-day demo, and it is available on multiple platforms like PC, iOS, Android, and Blackberry!

- Need a quick way to do trig calculations? See Page Tutor, and just fill in the sides or angles you know, and it does the rest.

- This link to CNC information comes from Robert Adams. His site, CAD2GcodeApps, is now offering all DXF to G-code conversion programs in one package for your lathe or mill.