Product Description

Our benchtop lathe has 17″ between centers compared to 8″ between centers on our tabletop lathe. Many machinists find the extra space between centers handy when working with a part held in a chuck and a larger tailstock chuck with a long drill bit in place. The combination of chucks, parts, and drill can eat up much of the available center-to-center distance, and a little extra capacity is often appreciated. The differences between the two lathe models are the additional 9″ of center distance and the addition of the zero adjustable handwheels and a rocker toolpost, making this lathe a good value for the extra cost.

Like our 8″ tabletop lathe, the 17″ benchtop lathe can turn a part up to 3.5″ in diameter over the bed or up to 1.88″ over the carriage without riser blocks. With an optional riser block, parts up to 6″ in diameter can be turned over the bed. The electronic speed control allows continuously variable speed control from 70 to 2,800 RPM without belt changes. A second pulley position is available that offers extra torque at low RPM if needed.

Our benchtop lathe is perfect for the customer looking for a mini lathe to make small, precision parts. All our lathes are made in the USA, and our customer service is second to none. Although our machines are small, they can produce high-quality precision parts. Our 17″ benchtop lathe will not only cut wood and plastic but is also rigid and accurate enough to cut aluminum and steel parts. This mini lathe is a desktop-size machine with full-size machine precision and accuracy.

- A powerful 90V DC motor with electronic speed controller*

- 2.75″ (70mm) x 6.0″ (152mm) crosslide

- 24″ (610mm) steel bed that has 17″ (431mm) between centers

- 2.5″ (63mm) resettable, zero adjustable handwheel on the leadscrew, a 2″ (51mm) resettable, zero adjustable handwheel on the crosslide feed screw, and a 2″ (51mm) resettable, zero adjustable handwheel on the tailstock. Each handwheel has laser-engraved aluminum handwheel collars

- Rocker tool post substituted for the standard tool post used on the short-bed tabletop lathes

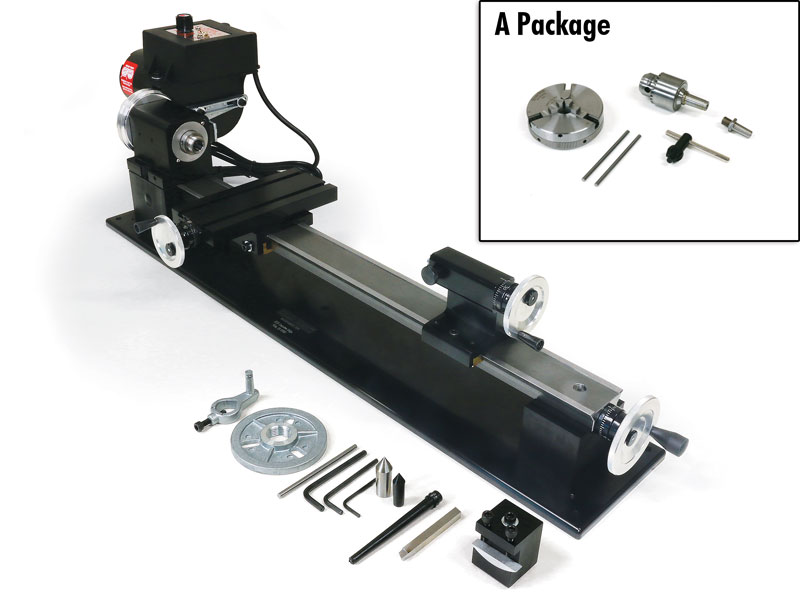

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual

* Not included with lathe without motor and speed control

The A Package includes:

- 3.1″ 3-jaw self-centering chuck

- 3/8″ tailstock drill chuck w/ key, #0 Morse arbor, #1 Morse arbor with drawbolt

Other ordering options:

Similar to the XYZ bases for our mills, you can now order the lathe without the headstock, motor, or speed control. Please see the selections in the drop-down menu above.