Product Description

This machine is based on our 14″ 2000-series mill. The 14″ mill base with ball screws comes with all-new saddles developed for the ball screws. The X/Y-mill saddle has been beefed up to accommodate the larger ball screws, and it has an electroless nickel/Teflon coating. This coating offers a rustproof hard surface, while the Teflon provides a friction coefficient of .1-.2u for smoother movement of the saddle and the table.

The new ball screw design for the column saddle reduces the overall Z-axis travel by 1.4″. Because the ball nut does not allow the column saddle to move down as far as the old style column saddle, we recommend upgrading to the 15″ mill column. This will allow you to move the headstock closer to the top of the mill table. However, you will still lose 1.4″ of overall travel in the Z-axis.

R: 14″ ball leadscrew mount

Click on the image for a larger view.

The Z-axis column bed on the 14″ ball screw mill is mounted directly to the swing arm with an arm mount, unlike the 2000 Deluxe mill that utilizes a movable clamping disk. This effectively eliminates the side-to-side rotational axis of the column bed.

SPECIAL NOTE ON THE COLUMN BED: The new column saddle on the Z-axis is longer, and the headstock mounts towards the bottom of the saddle. We did this because the column saddle Z-axis ball nut mount (P/N 45046) would not allow the original saddle to move low enough to the top of the mill table. Additionally, the P/N 45046 reduces the overall amount of usable Z-axis travel, and the maximum clearance above the table will be 2″ less than that of a standard leadscrew machine. In order to achieve greater travel and clearance above the table, we suggest that you upgrade to the 15″ Extended Mill Column Bed (P/N 45261) if you are ordering a new machine or doing a mill ball screw retrofit. The 15″ extended column bed makes up for the loss of travel in the Z-axis. It is also available with an electroless nickel/Teflon plating (P/N 45265) that adds increased lubricity and rust prevention.

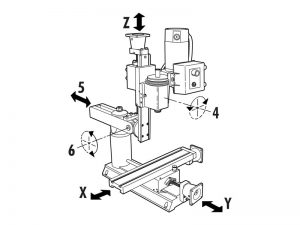

The Axes of Movement of a Sherline 14″ Ball Screw Mill

The table left/right movement is referred to as the X-axis. The table in/out movement is the Y-axis. Headstock up/down movement is referred to as the Z axis. The headstock can also be rotated on its saddle on Sherline mills (#4), the column ram can be moved in and out (#5), and the Z-axis column can be tilted forward and back (#6).

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

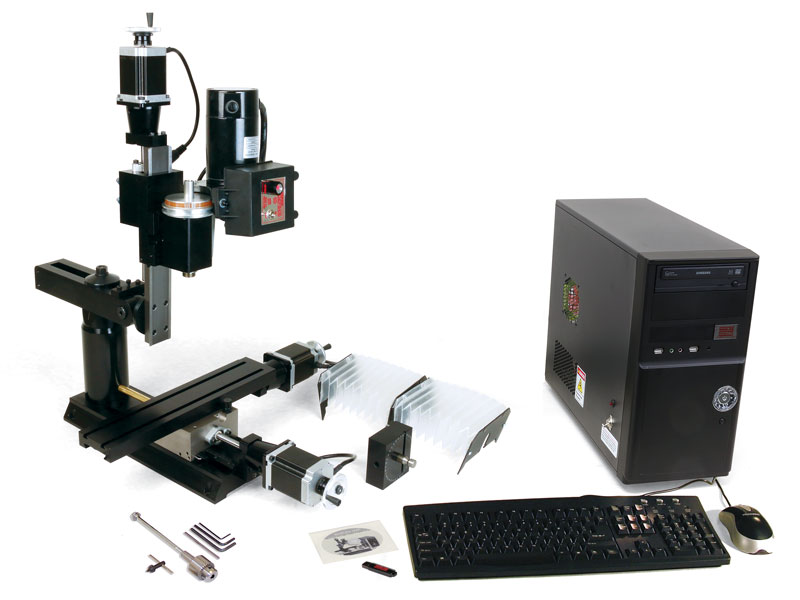

The 86820 CNC Package Includes:

- 14″ mill fitted ball screws and all new saddles developed for the ball screws.

- 3 High-Torque Stepper motors with couplings and mounts.

- A computer with 4-Axis Drive Box and Ubuntu Linux-based OS with LinuxCNC software preinstalled

- Keyboard and mouse

- Computer cables to the X-, Y-, and Z-axes are 69″ in length

- Instruction and utility CD. The CD includes complete instructions, and several free utilities to translate CAD files or TrueType fonts into G-code.

- A blank 4GB USB flash drive is also included

- 1-year warranty on all components for non-production use. 90-day warranty on CNC and computer-related components.

You supply only a monitor.

Standard equipment for the model 86820 CNC Mill includes:

- A powerful 90V DC motor with electronic speed controller

- 14″ base

- Electroless nickel/Teflon coated mill saddle

- 13.0″ (330 mm) x 2.75″ (70 mm) table with two T-slots

- 11″ standard mill column bed (Option to upgrade to a 15″ mill column bed with nickel/Teflon coating is available)

- Stepper-motor mounts with high-torque couplings

- The handwheels are included and can be mounted to the end of the stepper motors to maintain manual control when needed.* 2-1/2″ (63mm) adjustable “zero” handwheel on the Z-axis and 2″ (51mm) adjustable “zero” handwheels on the X- and Y-axes. Each handwheel has laser engraved aluminum handwheel collars

*NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed. - ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z-axis to help keep critical parts lubricated.

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- Accordion way cover