Product Description

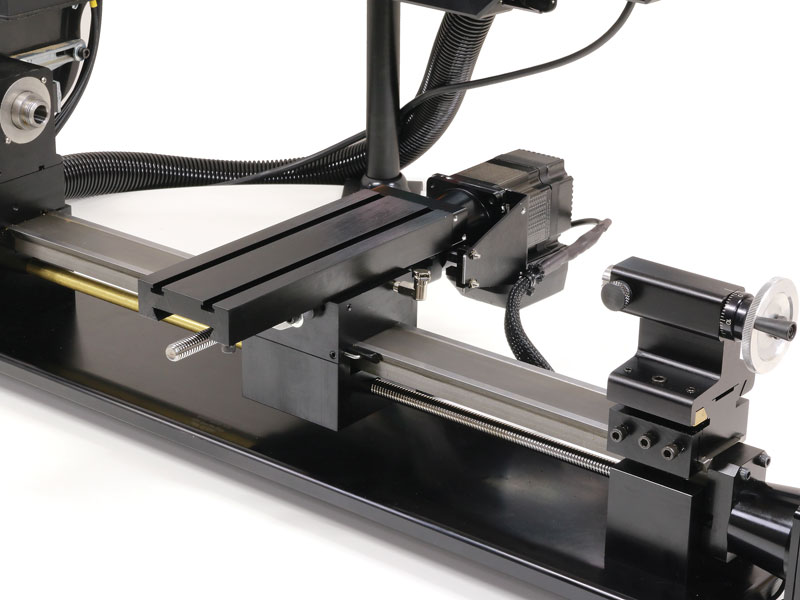

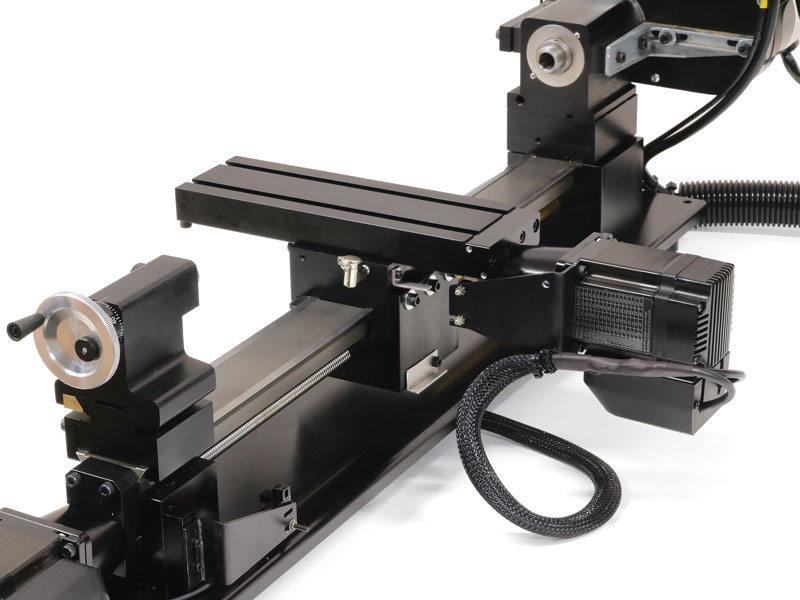

The ball screw lathe design is a reimagined version of our popular 17″ 4400-series benchtop lathe. The lathe has a new solid aluminum base, which creates a very rigid assembly, a beefed-up saddle to accommodate the ball screws, a larger 8″ crosslide, 36V closed-loop stepper motors with #23 NEMA frames, motor mounts with high-torque couplings, and C5 bearings in the headstock for smoother spindle operation.

Ball Leadscrew Specifications

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

The ball screws are only available in metric.

About the Sherline/MASSO CNC G3 Touch Controller

The MASSO Touch Controller with power supply and spindle drive card lets you input data to the controller via a state-of-the-art touch screen. With MASSO, you can write your CNC programs on your computer (Windows, Mac, Linux, etc.) and then transfer your program to the controller via a USB flash drive. You no longer have to use a dedicated operating system like Linux or Mach 4 to control your machine.

The Touch Controller includes:

- Industrial cable system from the controller to the machine

- 36-volt power supply

- Touch-controller stand

Do you want to know more about the Sherline/MASSO G3 CNC controller? Here are some resource links for your reference.

- Sherline/MASSO G3 Help page

- MASSO G3 FAQs page

- MASSO G3 Videos page

The MASSO Accu-Pro Turn Benchtop Lathe System Package includes the following:

- 17″ benchtop lathe fitted with ball screws and an all-new saddle developed for the ball screws

- A Sherline/MASSO G3 Touch Controller

- G-code Spindle Speed Control with threading capability

- An optical encoder

- WiFi is standard with the MASSO G3 Touch Controller

- Two 36-volt, Closed-Loop, High-Torque Stepper motors with a 70 in/min maximum feed rate

- Professional cable wraps and covers for the X- and Z-axis

- MASSO homing sensors on all axes

- USB 4 GB flash drive (With software, machine settings, sample programs, and PDF instructions included.)

- 1-year warranty on all machine components for non-production use. 90-day warranty on CNC and electronic controller-related components

Standard equipment for the Accu-Pro Turn Benchtop Lathe includes the following:

- A powerful 90V DC motor with an electronic speed controller

- 24″ (610mm) steel bed that has 17″ (431mm) between centers

- 8″ crosslide

- Headstock with #1 Morse taper, 3/4 x 16 spindle thread with precision C5 bearings. You can also order the optional nickel-plated 3C spindle with .001″ or less TIR*. (*A TIR of .0005″ or less can be requested for an additional charge.)

- Stepper-motor mounts with high-torque couplings

- 3/8″ Insert holder tool post (P/N 7600)

- Oil reservoirs on the X/Z saddle to help keep critical parts lubricated

- Brass leadscrew cover that keeps chips off the front of the Z-axis leadscrew

Optional Accessories for the Accu-Pro Turn Lathe:

Click the Optional Accessories tab above to see which accessories are available for the Accu-Pro Turn Lathe.