Anyone who visits the San Diego area is welcome to stop by and visit our factory. For those of you who can’t get to Southern California, this page will give you a brief tour of the production plant and offices. Our new 66,000 square foot facility is now complete, so production, assembly and our administrative offices are once again under one roof. We invite you to stop by and tour the facility, but if you can’t, please enjoy the following photo tour. (For safety reasons, actual factory tours are limited to those 14 and older. The showroom is open to all ages with appropriate adult supervision, but display heights were not designed for viewing by children.)

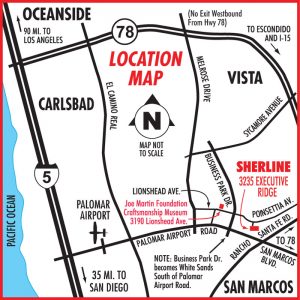

If you are in Southern California, please come by and visit us. Vista is about 35 minutes North of San Diego on Interstate 5 and about an hour and a half to two hours South of Los Angeles. We are always glad to show people our facility. No appointment is necessary.

Assembly and Factory Tour Hours: Tuesday-Friday 7:30-3:00, Excluding Holidays

Showroom Hours: Tuesday-Friday 7:30-3:00

A Photo Tour of the Sherline Factory

Click on any image and use the “forward” and “previous” arrows to take a tour of the Sherline factory.

To end the tour just click in the gray area.