Product Description

NOTICE:

Before you purchase this accessory, you must measure the thru-hole diameter of your spindle. It should be .408″ minimum for this accessory to work correctly (see the diagram below for reference).

If your machine is an older machine, the thru-hole size in your spindle may be too small. The original spindles had a .406″ thru-hole, which was clearance for a 3/8″ tool. Because this offered plenty of clearance for a 3/8″ tool, the .406 hole was drilled, and not held to a very tight tolerance. Sometimes the drill walked a bit, or the hole was slightly undersized. When Joe Martin designed the sensitive drill attachment (SDA), he designed it with very little clearance between the brass shaft of the SDA and the .406 hole.

Since then, we have opened up the thru-hole diameter to .410 – .411 and the hole is reamed to size.

You must also check for a misalignment step in the .406 hole about 1-1/2″ from the pulley end of the spindle. The older spindles were drilled from both ends, and on some parts, the drill walked off center. This will also cause a clearance problem for the SDA.

If you would like to purchase the SDA for your machine, and your thru-hole is too small, or there is an alignment issue, we will offer to ream your spindle to size, free of charge if you are willing to pay for the shipping.

To acquire this free service, call us at (760) 727-5857 and request an RMA# for your headstock.

If you place an order for an SDA at the same time and send your headstock in, we will machine your headstock spindle, and fit your SDA to the headstock to guarantee proper fit and function.

Click on the image for a larger view.

About the Sensitive Drilling Attachment

The sensitive drilling attachment makes it quicker and easier to drill small holes without breaking drill bits. Using a quill or handwheel feed to advance drills smaller than 1/16″ in diameter can lead to broken drills, because the leverage provided by those methods makes it difficult to “feel” how the drill is cutting. If you don’t need the micrometer depth control of a handwheel feed, the sensitive drilling attachment will make your small hole drilling tasks easier.

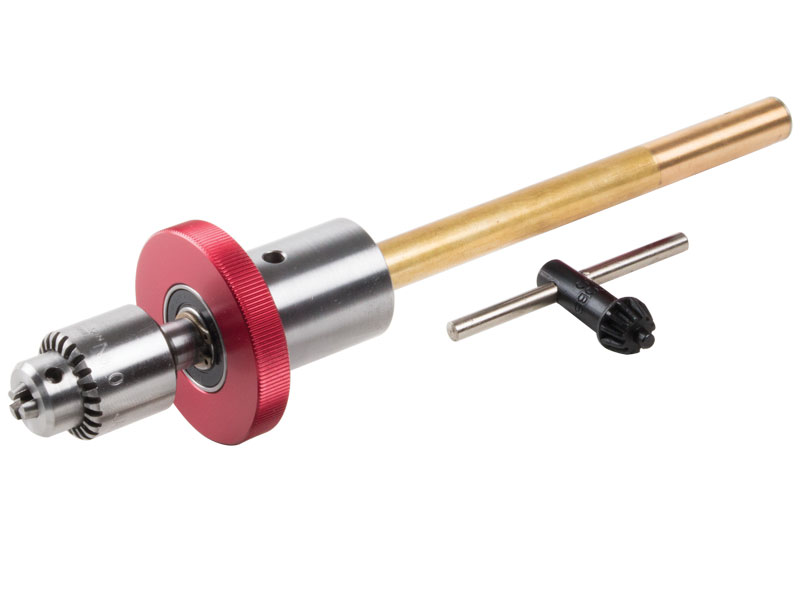

The attachment consists of a 5/32″ Drill Chuck that slides on a central shaft. The shaft attaches to the spindle with a holder that threads onto the 3/4-16 spindle thread in seconds much like an end mill holder. A spring contained inside the brass spacer tube helps support the chuck and return it to the “up” position. The chuck will hold drill bits from 5/32″ to as small as #80 (.0135″)

The attachment is easy to install in a few seconds. Just insert the spring tube up into the spindle and thread the attachment body onto the spindle thread. To use, grasp the red, knurled ring which rides on a ball bearing on the main shaft. Pull the drill downward against the spring tension and let it return when done.

If you drill a lot of small holes, this attachment will come in handy. It may even pay for itself in the long run in savings due to less breakage of expensive small drills.