About the Insert Boring Bars with Two Flats

When we designed our gang-tooling tool post (P/N 5930), it was specifically for our customers who wanted to convert their Sherline lathe into a “Chucker Lathe” or gang-tooling lathe. Most of the parts to be manufactured on a chucker lathe are going to be in the range of 1/2″ (13mm) diameter or smaller. The distance between centers on our gang-tooling tool post is 1.5″ (38mm). With these part sizes and the spacing, we realized that our boring bars could be used as both boring bars and outside diameter turning tools.

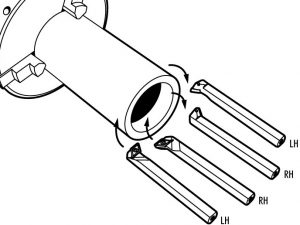

We added a second flat to our standard boring bars* so they could be held with the insert face up or face down. This modification allows the left hand 55-degree and 80-degree boring bars to be used as O.D. turning tools on either the front or back side of the part. Click on the Instructions tab for more details on using the boring bars with two flats.

* NOTE: Standard 3/8″ boring bar part numbers: 2259 RH 55°, 2260 RH 80°, 2263 LH 55°, 2264 LH 80°

Consider the options and possibilities of using these boring bars as turning tools as well as boring bars. Also, consider using these boring bars with the insert face down to reduce chip buildup on top of the insert.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

About the Insert Boring Tool Holders

The 3/8″ diameter boring bars hold a carbide insert secured with a Torx screw. Each comes with 2-sided 55° carbide insert and Torx wrench. The 55° RH boring tool will fit into a 3/4″ starting hole. The 55° insert will cut into sharper corners, while the 80° holder offers a little more strength for roughing cuts. The 3-1/4″ long holder can bore a hole a little over 2″ deep with two fastening screws tightened on it. The holders are made from 1144 Stress-proof steel with a black oxide finish.