Product Description

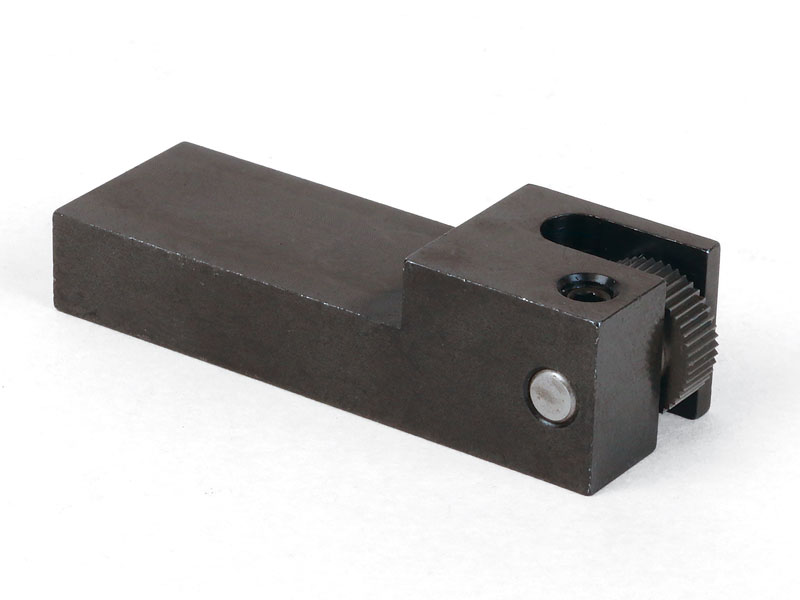

About the Bump Knurl Tool Holder

Our bump knurl holder was designed primarily so customers who have CNC machines could add a knurling operation to their program, but it can also be used on a manual lathe. This holder is the same style that is used on full-sized CNC machines. The part is held in position using the 3/8″ Insert Holder Tool Post (P/N 7600, not included).

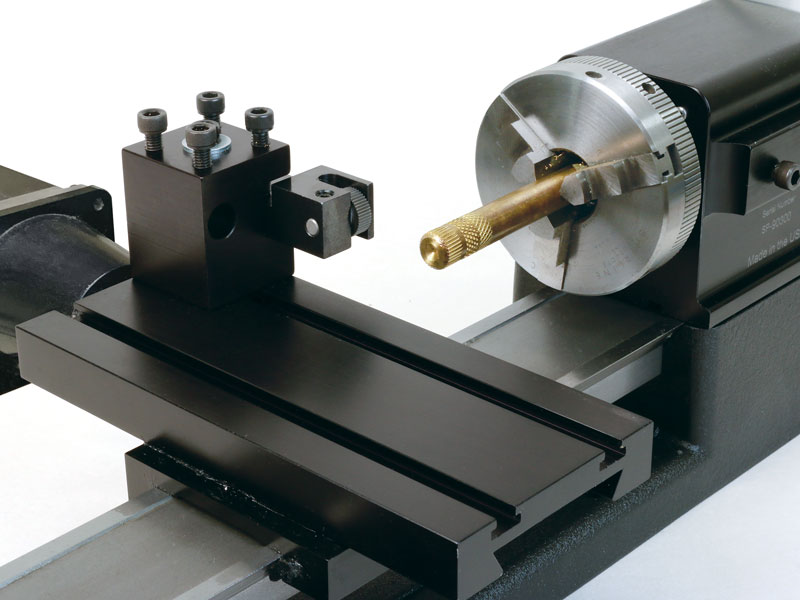

P/N 2275 Bump Knurl Tool Holder shown engaged with a part.

Knurl size limitations with the Bump Knurl Tool

There are limitations to the knurl size and method of holding your part: Knurls from 40 TPI (threads per inch) and higher will work well on our machine. Coarser knurls from 32 TPI and lower will not work well. The exception to the rule is the diamond knurl. Because the diamond knurl is a male pattern, it can cut a larger TPI, so the 25 TPI that we offer is fine.

The bump knurl tool will handle stock diameters up to 1/2″ (12.5 mm), while it is turned in the lathe, creating a knurled pattern.

NOTE: The knurling tool was not designed for use with riser blocks.

Other size knurls for spiral, straight, or diamond patterns are also available.

Select the knurl(s) of your choice in the drop-down menu above.*

*NOTE: Each knurl is an additional cost.

Stock Size Using the Bump Knurl Tool Holder

The diameter of the stock that can be knurled using the Bump Knurl Tool Holder depends on several factors.

- The process of bump knurling exerts a lot of force on the side of the part.

- The amount of force depends on the size and depth of the knurl.

- The side force will cause the material to flex away from the knurl.

- The amount of flex will depend mainly on how far away from the collet or the chuck the actual knurling operation is being performed. The farther away from the collet, the more the part will flex. The smaller the part diameter, the less side force required to cause the part to flex.

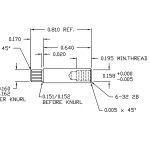

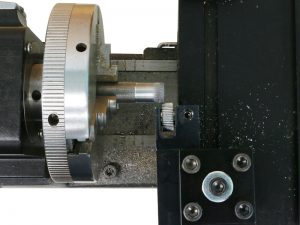

- The part in the images below (Examples 1 & 2) is our handwheel knob shaft (P/N 42050). This part is 3/16″ diameter, and the material is 12L14 steel. The bump knurling operation on this part is done as close to the collet as possible.

- After your first part is knurled, you may find that your knurl is tapered. This is due to the part flex. You can compensate for this taper to some extent by turning the bump knurl holder at a slight reverse taper angle. This will cause one side of the knurl to make contact with the high side of the tapered knurl first, resulting in a less tapered knurl.

- Knurling parts with a diameter as small as 1/8″ should be possible if the process is done close to the collet. Even smaller diameters are possible. Again, the size and depth of the desired knurl are also factors.

-

Example 1: Handwheel shaft

Click on the image for a larger view.

-

Example 2: Handwheel shaft diagram

Click on the image for a larger view.