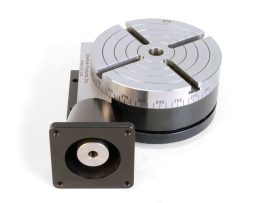

Product Description

The rotary table tooling plate is just under 5-1/2″ in diameter and comes with a pattern of 10-32 holes in the surface to facilitate mounting fixtures for machining. Four countersunk holes are provided for mounting it to the T-slots in the Sherline rotary table, and mounting screws and T-nuts are included. The 1/2″ aluminum plate is made from aircraft grade 6061 T6 aluminum and can be drilled and tapped with additional holes as needed for your special jobs.

The pre-drilled holes are not tapped all the way through. This is to protect the surface of the rotary table from hold-down screws that might be too long. If when tightening a hold-down screw you feel it begin to bind, that means the screw is too long and you need to remove it and use a screw of the appropriate length.

On the bottom of the tooling plate is a raised boss that registers in the center hole of the rotary table for alignment. Placing the T-nuts in the slots of the rotary table so they align with the table’s outer machined reference ring will put them in alignment with the mounting holes for easy attachment of the fixture to the table.