Product Description

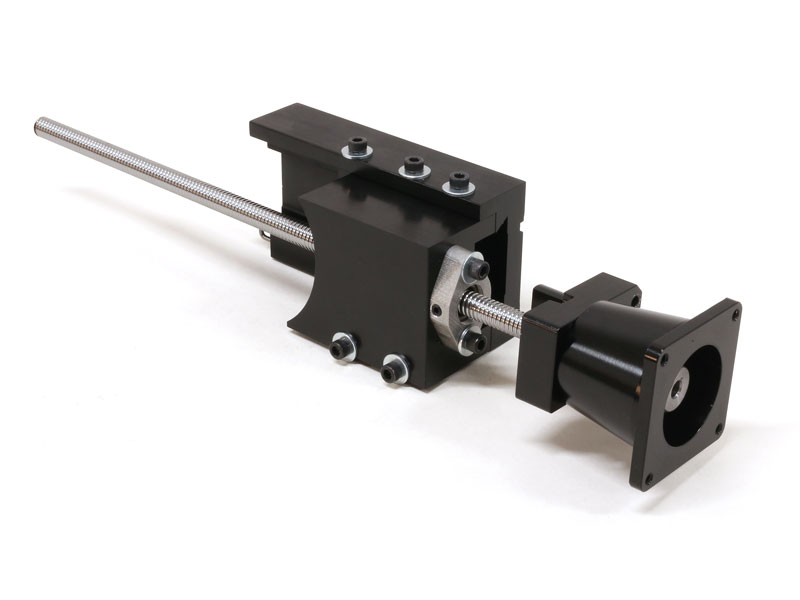

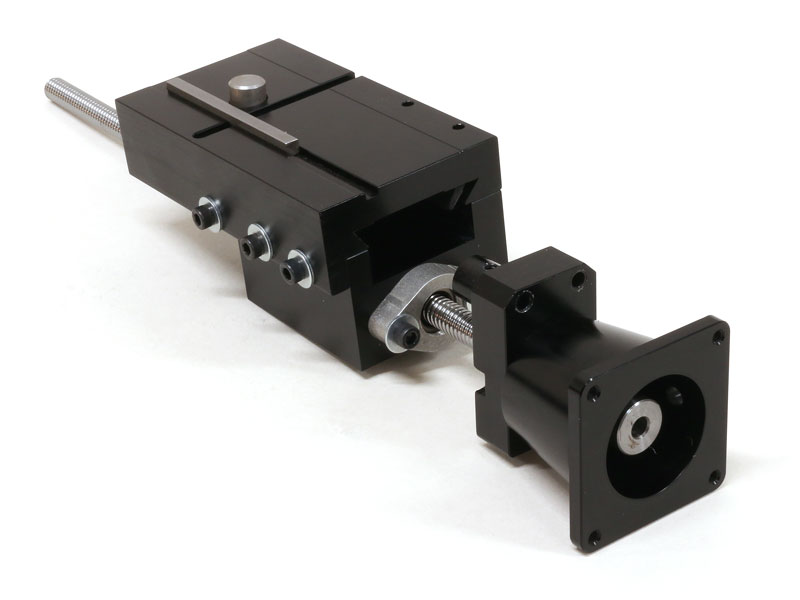

The key upgrade parts for this ball screw retrofit kit include ball leadscrews, stepper motor high-torque coupling, the ball screw mill saddle (with nickel / Teflon plate) for the X/Y-axes, and a ball leadscrew, stepper-motor coupling, vertical milling column saddle for ball screws, and column saddle Z-axis ball nut mount.

Ball Leadscrew Specifications

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

Regarding Retrofits

- The charge for all ball leadscrews is the same, regardless of the overall length. This is because the manufacturer does not give us a price break on the shorter screws (in fact, they wanted more for a 6″ ball screw). All screws come in at 400mm (15.75mm) long, and we cut them to length to fit the individual machine axis.

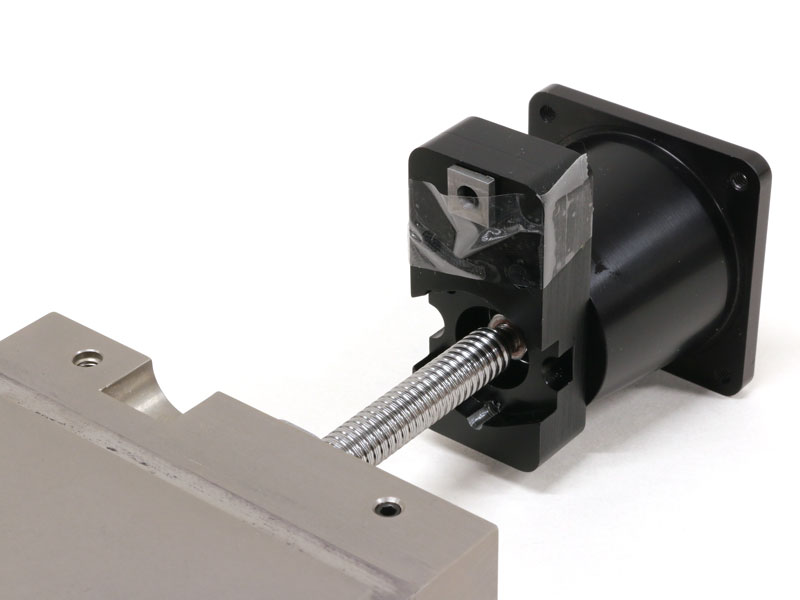

- All retrofits come with stepper-motor mounts, high-torque couplings, bearings, preload nuts, and ball screws fully assembled in our factory. We do not sell these parts individually for you to assemble.

- The ball leadscrew and the rest of the assembly are assembled and checked in our factory. We place an O-ring on the end of the ball screw below the saddle, away from the motor mount. The O-ring is placed there to help ensure that the ball nut does not thread itself off the ball screw. If the ball nut threads off the ball screw, the balls in the ball nut will come out. At this point, the ball screw is scrap. There is no way to fix it! For this reason, the O-ring is to remain on the ball screw until the ball screw assembly is fully assembled on your machine. After you have assembled your ball screw on your machine, you may remove the O-ring.

NOTE: On retrofits, the only way your ball leadscrew can have excessive slop (backlash) is if some of the balls have come out of the ball nut. We will not replace ball leadscrews that have excessive slop (backlash)!

SPECIAL NOTE ON THE COLUMN BED: The new column saddle on the Z-axis is longer, and the headstock mounts towards the bottom of the saddle. We did this because the column saddle Z-axis ball nut mount (P/N 45046) would not allow the original saddle to move low enough to the top of the mill table. Additionally, the P/N 45046 reduces the overall amount of usable Z-axis travel, and the maximum clearance above the table will be 2″ less than that of a standard leadscrew machine. In order to achieve greater travel and clearance above the table, we suggest that you upgrade to the 15″ Extended Mill Column Bed (P/N 45261) if you are ordering a new machine or doing a mill ball screw retrofit. The 15″ extended column bed makes up for the loss of travel in the Z-axis. It is also available with an electroless nickel/Teflon plating (P/N 45265) that adds increased lubricity and rust prevention.

Regarding the Hole Modification through the Mill Column Base

For all mill retrofits, you must drill a ½” hole through your column base. This is a clearance hole for the brass cover tube to go through the column base. On page 5 of the instructions, there are copies of the prints for both the standard column base and the rigid and 2000 column bases.

If you would like us to do the machining, the cost will be $60.00 plus your return shipping. You will need to select this option from the drop-down above, and we will provide information on how to send your column base back once we receive your order.

You can also purchase a new column base with the ½” hole already drilled. The base for our 5000/5400 series mills is part number 50054, part number 56714 for the 2000 series mills, and part number 50055 or 50056 for the rigid column bases.