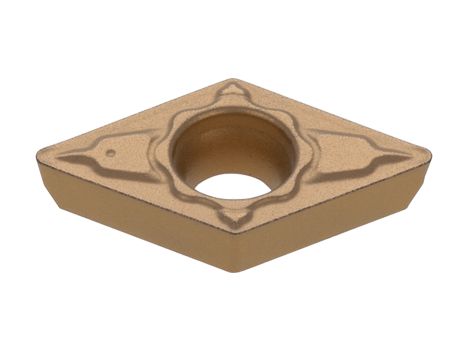

Product Description

About the Replacement 55° Carbide Insert

Though not inexpensive, when you consider you are getting four cutting tools in one and are saving a lot of time in tool sharpening, it is a pretty good deal.

Carbide cutters give good finishes on hard-to-machine materials such as cold-rolled steel. They will also work on aluminum, brass, or leaded steels, lasting practically forever. However, the best finishes on those materials are still achieved with a good, sharp, high-speed steel tool.

55° Carbide Insert Tool Holders

This is a replacement carbide insert for the following tool holders: