Product Description

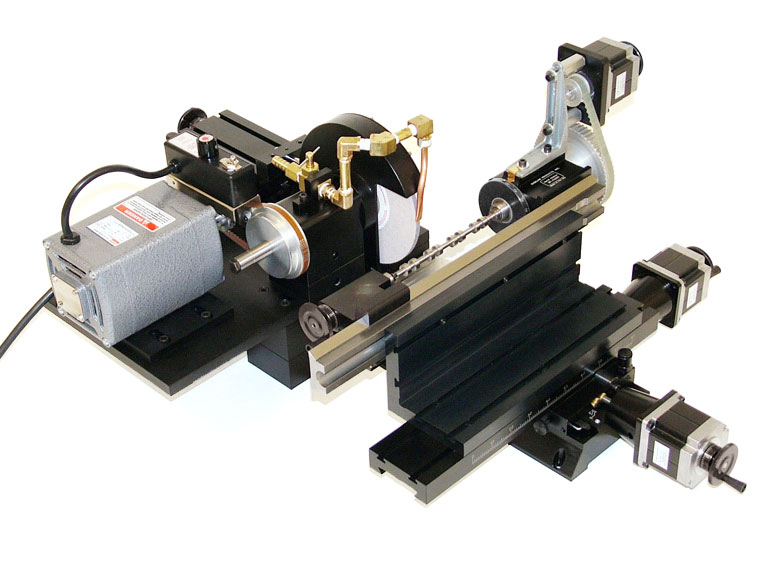

About the Sherline CNC Cam Grinder

When building a model engine, one of the more difficult components to make is usually the camshaft. There are ways to make a mechanical grinder to do the job and make built-up cams, but this is one job where computer control really makes sense. A specially developed Sherline software program allows you to input simple measurements taken from your cam drawings and then output the g-code needed to run the CNC stepper motors that control the rotation of the cam and the lobe’s shape. Remember that this grinder can also be used to grind small cams for other prototype applications besides model engines.

The Sherline cam grinder was designed with the home shop machinist in mind. We have assumed that the user has some knowledge of g-code, CNC, and how to square up or “tram in” a machine, so all axes are properly aligned. The machine is carefully pre-aligned at the factory, but rough handling in shipping could knock something out of alignment. As with any new machine tool, it is the operator’s responsibility to assure that it is properly aligned in all directions before attempting to grind a cam accurately. If you are not familiar with the procedure to align a machine, contact Sherline for advice.

The grinder itself features the solid, well-engineered construction you have come to expect from Sherline machine tools. If you are making a few cams for your own use, making cams for others for sale, or a club looking to invest in a machine for the use of all the members, this machine will offer a way to take advantage of modern CNC technology to make accurate, well-formed cams with much less time and effort compared to manual methods.

What’s included:

The purchaser who already owns a Sherline CNC system can purchase just the cam grinder as P/N 8650, and it can be used with the Linux computer running LlinuxCNC and 4-axis driver that came with your mill or lathe. If you do not already have a Sherline computer to control the stepper motors, you can purchase P/N 8655 that includes a computer and 4-axis drivers.

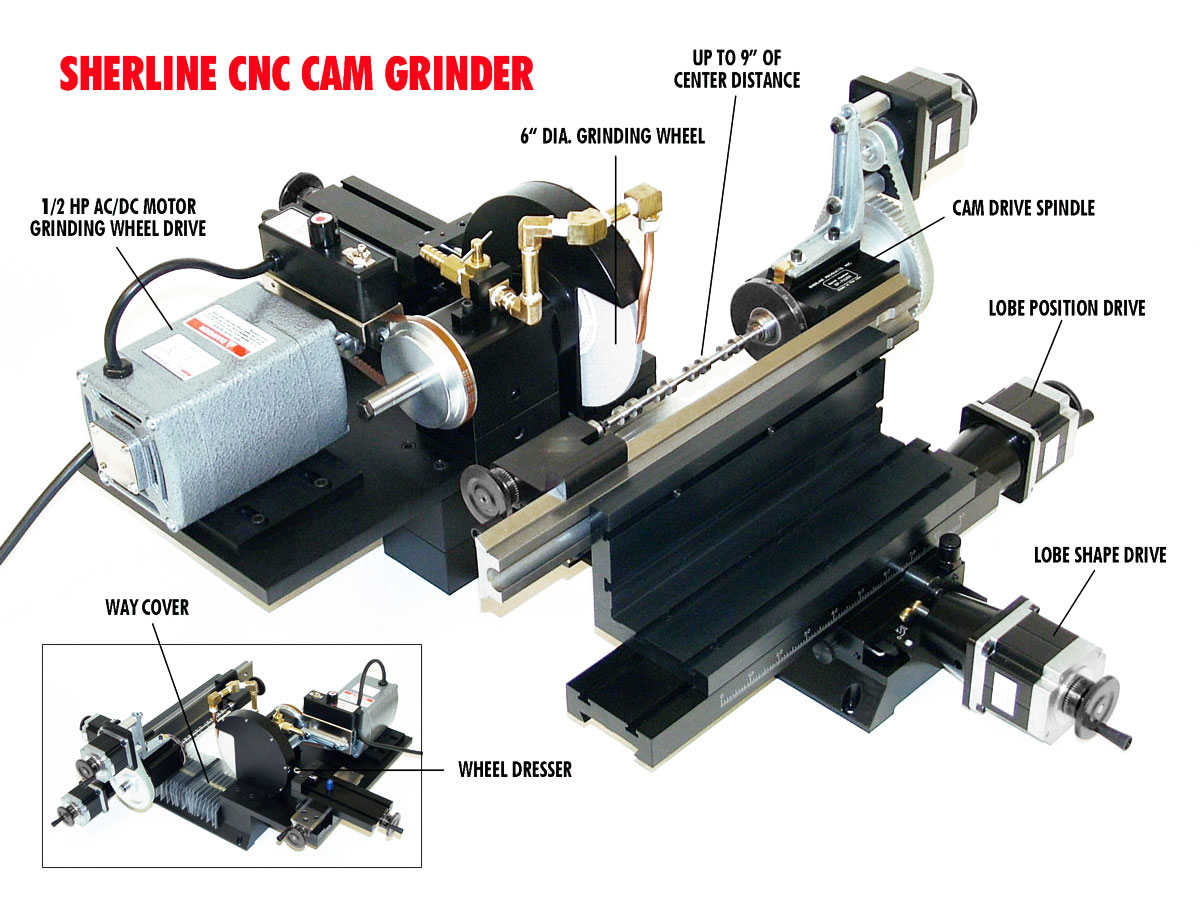

Features include:

- Powerful 1/2 HP grinder motor (120 VAC)

- 3 DC stepper motors with manual control handwheels

- Flexible way covers on Y-axis keeps water and grinding debris off Y-axis leadscrew

- Holds cam blanks up to 9″ long in the collet (8″ long between centers)

- A tough, black anodized finish on aluminum parts

- Standard 1-year Sherline warranty for home shop (non-commercial production) use

- 6″ grinding wheel and built-in diamond wheel dresser included

- Collet holding fixture, #0 Morse dead center, faceplate, hex keys, and Tommy bar

- Laser engraved degree collar on spindle headstock

- Brass coolant plumbing factory assembled

- Available with computer and drivers or without computer and drivers (for those who already have a Sherline CNC mill or lathe)

NOTE: Chucks and collets available but not included.

What is not included:

Chucks and collets specific to your job are available but are not included. To save shipping costs, some common but difficult to ship items that can be purchased locally by the user are not included. These include a metal automotive garage floor oil-drip pan for collecting the coolant, a small submersible water pump for coolant, a few feet if 1/2″diameter plastic tubing and a 5-gallon bucket to contain the coolant. The machine will be shipped partially assembled. Final assembly and truing up must be done by the end-user, as it would be impossible to ship the entire, assembled machine and expect it to hold tolerances after the shipping process. Technical assistance will be available to help the user through this process.

NOTE: The grinder motor operates on 110-120 VAC, 60 Hz current.