About the Sherline/Acorn CNC Controller

Based on customer requests, feedback, and our in-house testing, we now offer the Centroid Acorn CNC Controller with our Sherline machines. The Sherline/Acorn CNC Controller is a Plug-and-Play unit with no complex wiring required.

Centroid CNC is an American company in Howard, PA, founded in 1979. The Acorn CNC Control is a top-of-the-line CNC control that is reliable, high-performance, and industrial quality.

Sherline has always designed our accessories and machines to be backward compatible. For us at Sherline, the Acorn controller offers our customers a quality CNC controller that can be used with our newest and older machine models. The Acorn CNC controller is an excellent choice for Sherline customers looking to upgrade their older machine and/or CNC control.

The Sherline/Acorn CNC control (P/N 9400) comes in a custom housing with all the desired components inside and all necessary connections on the front and rear panels. This custom control housing has the Acorn board and the relay card mounted inside. It includes all the wiring for the DB9, DB25, 2-wire Molex connectors, the Ethernet connection, the power supply, the circuit breaker, and the cooling fan.

Getting started with Acorn CNC

For customers interested in the Acorn controller, we suggest you watch the videos in the links below. Many of our customers are new to CNC, and one of the questions we often receive is, “Does this controller generate g-code programs?” Until now, the answer has been no. For most CNC controllers, the g-code program is created using separate CAD/CAM software. This requires additional expense and time to learn the CAD/CAM program. The Acorn has one of the best “conversational” programs that we have seen on any controller, which is their “Intercon Conversational Software.” Watch these videos, and you will see how easy it is to take your part from idea, hand sketch, or DXF file to a running g-code program using only the Acorn control.

- Centroid CNC Control User Training Video: CNC Milling Machine Training

- Centroid DXF Import Using Intercon Conversational Software

- Centroid Acorn Lathe Conversational Programming Primer

Sherline/Acorn CNC controller features:

- Custom control housing

- External ethernet connection

- Power switch and power light

- Cooling fan

- Three DB9 connectors, three DB25 connectors, and three 2-pin Molex connectors

- Push-to-reset circuit breaker

- Acorn CNC control board

- Acorn Plug-and-Play Relay Module

NOTE: The Plug-and-Play Relay is mounted inside the control housing, wired to the Acorn board, and wired to the DB25 connector on the back panel of the control. Click the Instructions tab above for a PDF link for more plug-and-play relay information. - Dual power, 5 VDC, and 24 VDC logic power supply (50/60 Hz 100-120 VAC and 208-240 VAC input power)

- 15’ Shielded Ethernet cable to connect the controller to a computer

- External e-stop with 2ft. cord

- The control will connect to any of the 24v stepper motors we sell with our machines. The Acorn controller will NOT work with the MASSO 36v closed-loop stepper motors.

- If you use our 24v stepper motors, you will use our 4-axis driver box (P/N 8760). The driver box connects to the DB25 connector on the backside of the control.

- If you use your own stepper motors and drives, you connect them to the “Aux 4-axis” DB25 connector.

- For wiring information for DIY customers, go to the Specifications tab above.

A free version of Centroid CNC12 is included with each Acorn kit for setup use. However, it is STRONGLY RECOMMENDED that you purchase the Centroid Acorn “Pro” CNC12 Software License. Use the radio-button menu above to select the software version for your mill or lathe (NOTE: The software is board-specific). CLICK HERE for Acorn “Pro” CNC12 Software License details.

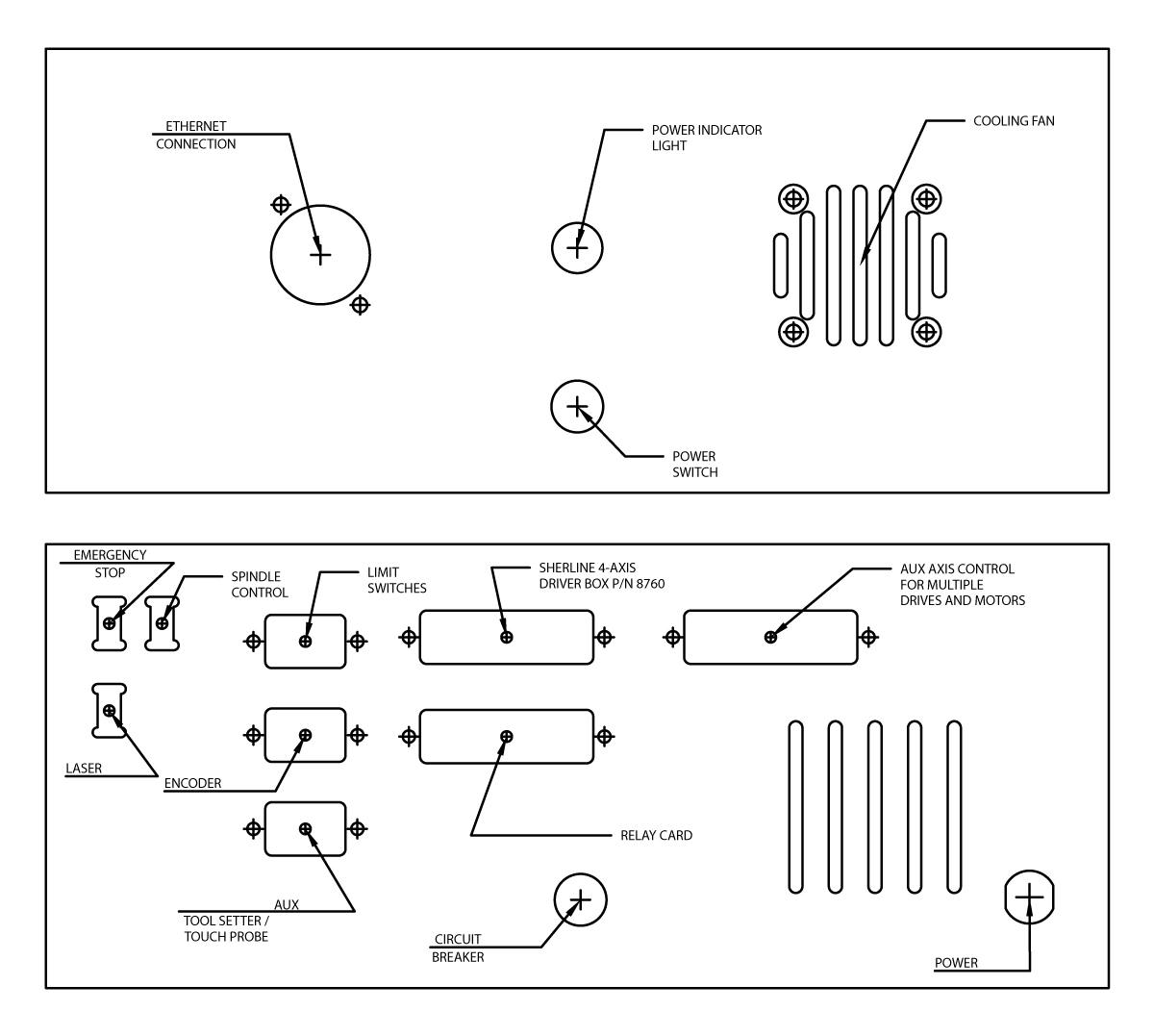

The components and connections on the front control panel:

- Ethernet connection

- Power switch and power LED light

- Cooling fan

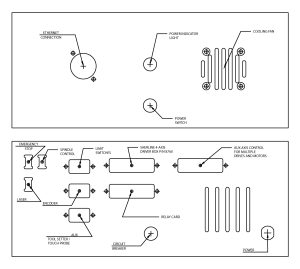

The connections on the back control panel:

- Three DB25 connectors for 1) Sherline 4-axis Driver Box, 2) Aux 4-axis Control for multiple drives, stepper or servo motors, 3) The relay card

- Three DB9 connectors for 1) Limit switches, 2) External Encoder*, 3) Aux Tool Setter or Touch Probe (only one can be connected, not both)

*Download the Sherline/Acorn Spindle Speed-Control information - Three 2-wire Molex connectors for 1) E-stop button, 2) Spindle control, 3) Laser

Selecting your controller options:

Our Sherline CNC customers fall into a few categories.

- DIY Customer

For DIY customers who buy CNC-ready machines and install their own hardware, such as motors, drives, and encoders, purchase the Sherline/Acorn CNC Controller (P/N 9400) without any options. - CNC Upgrade Customer

Customers who are interested in a controller upgrade for their current CNC machine. If you already have a Sherline Linux PC or a 4-axis driver box, purchase the Sherline/Acorn CNC Controller with a spindle control isolator board and an External Encoder to fit your headstock (standard or 3C). - CNC Turnkey Customer

Customers who want to buy a complete CNC turnkey system. Select your Sherline CNC-ready machine and 24v stepper motors. Then, add the 4-axis driver box, the spindle control isolator board, and an external encoder to fit your headstock of choice.

Our Acorn CNC controller is designed for the different needs of these end users. The Sherline/Acorn CNC Controller base model (P/N 9400) is for the DIY customer. See the Options tab above for detailed information regarding the drop-down menu options.

NOTE: You must have a motor drive or the spindle control isolator board, along with the external encoder, to control the spindle via G-code. They work in unison to acquire the correct spindle RPM.

Customer Requirements for Centroid Acorn:

Click the Instructions tab above to download the What Customers Need to Supply to Use Centroid Acorn Information.

Optional equipment

You can use the Sherline/Acorn CNC controller with or without limit switches. CLICK HERE for more information on Limit Switch Assemblies for Sherline lathes and mills.