Product Description

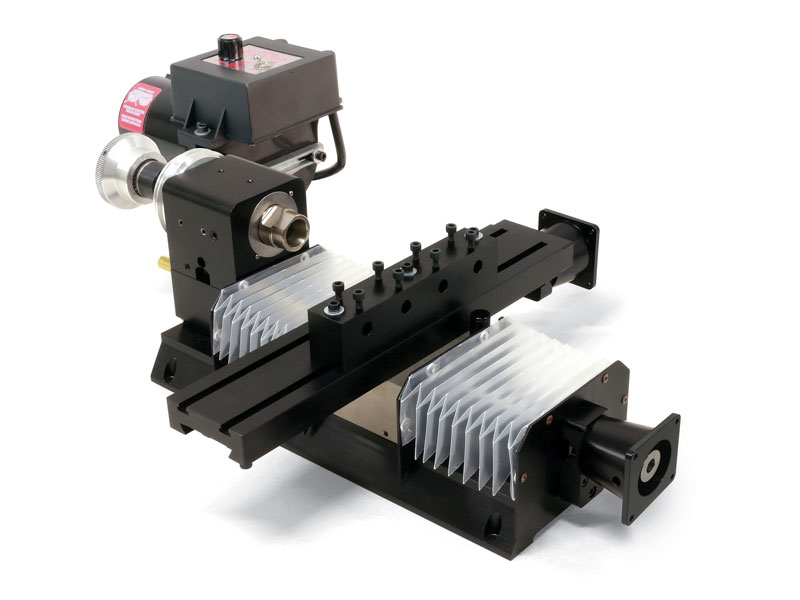

We designed our CNC chucker lathe for our industrial customers who want the convenience of using multiple tools in a single setup. The lathe has a 13″ crosslide that accommodates the 3/8″ gang-tooling tool post and two optional tool posts that can be used for boring and parting tools (tools not included).

NOTE: Machines equipped with ball screws will not include laser-engraved scales on the mill table or the mill base.

Standard Features Include

- Ball Leadscrew*: Rolled Ball Screw with BSH Nut .10mm Diameter, 2mm Lead. C7 Accuracy, P1 Preload. The linear accuracy is 50 micrometers/300mm

- 3/8″ Gang-tooling tool post that holds up to four tools

- 14″ Base (Optional upgrade to 18″ available)*

- 13″ Mill table (Optional upgrade to 18″ available)*

* NOTE: The axis travel will increase when you upgrade to a longer table or base. The increase will be equal to the length difference for the axis (click the Specifications tab for details). - Mill Saddle: Has electroless nickel coating with Teflon. This coating offers a hard surface that is rustproof. The Teflon provides a friction coefficient of .1-.2u for smoother movement of the saddle and the table.

- 3C Collet headstock: The 3C headstock’s TIR (total indicator runout) is rated at 0.001″ (.0005” or less upon request for an additional $60.00 charge). The 3C spindle is electroless nickel plated to aid in rust prevention and increase its surface hardness for durability.

- Powerful 90V DC motor with electronic speed controller

- Accordion way cover and brass-tube leadscrew cover

- The maximum feed rate is 32 in/min.

- The largest diameter through the collet is ½” (13mm). NOTE: collets are not available through Sherline Products. We recommend buying them from Hardinge.

- 1-year warranty on all components for non-production use. 90-day warranty on CNC and computer-related components.

*NOTE: See the Specifications tab located above for the Ball Leadscrew and High-Torque Stepper Motor specs.

Chucker Lathe Photo Gallery

Note: Photos show chucker lathes with various options

- Chucker Lathe with stepper motors

- Mounted 3/8″ Gang-tool post

- Ball screw

- Ball screw

- 2-amp high-torque stepper motors

- 3C headstock

- Brass tube leadscrew cover

- Mounted tools on 13″ crosslide (sold separately)

- Mounted tools on 13″ crosslide (sold separately)

- With 3C collet closer (sold separately)

- With 3C collet closer (sold separately)

- Shown with optional 18″ base and 18″ table

- Mounted tools on 18″ crosslide (sold separately)

Chucker Lathe Accessories

Chuck Adapter

- P/N 10670 3C to 3/4-16 Chuck Arbor (You need this arbor to use a chuck on the 3C headstock)

Tool Adapters

Tool Posts

- P/N 5935 5/8″ Gang-Tooling Tool Post

- P/N 5931 3/8″ Rear Side Cutoff Multi-Tool Holder

- P/N 5932 3/8″ Front Side Multi-Tool Holder

- P/N 5936 5/8″ Rear Side Cutoff Multi-Tool Holder

- P/N 5937 5/8″ Front Side Multi-Tool Holder

Boring Tools*

- P/N 2266 Carbide Insert RH 55° 3/8″ Boring Bar w/2Flats

- P/N 2268 Carbide Insert RH 80° 3/8″ Boring Bar w/2Flats

- P/N 2273 Carbide Insert LH 55° 3/8″ Boring Bar w/2Flats

- P/N 2274 Carbide Insert LH 80° 3/8″ Boring Bar w/2Flats

*We added a second flat to our standard boring bars so they can be held with the insert face up or face down.